REDUCING TEE

We has more than ten years of experience in the production and export of plastic valve/pipe fittings. with the development of the company, we have added our production machines, production technology and production procedures, greatly improving our production efficiency and greatly quick delivery time .If you are interested in our factory, welcome to visit our factory in China. The entire production process, from product conception to delivery to the customer, guarantee the highest quality and to minimize errors.

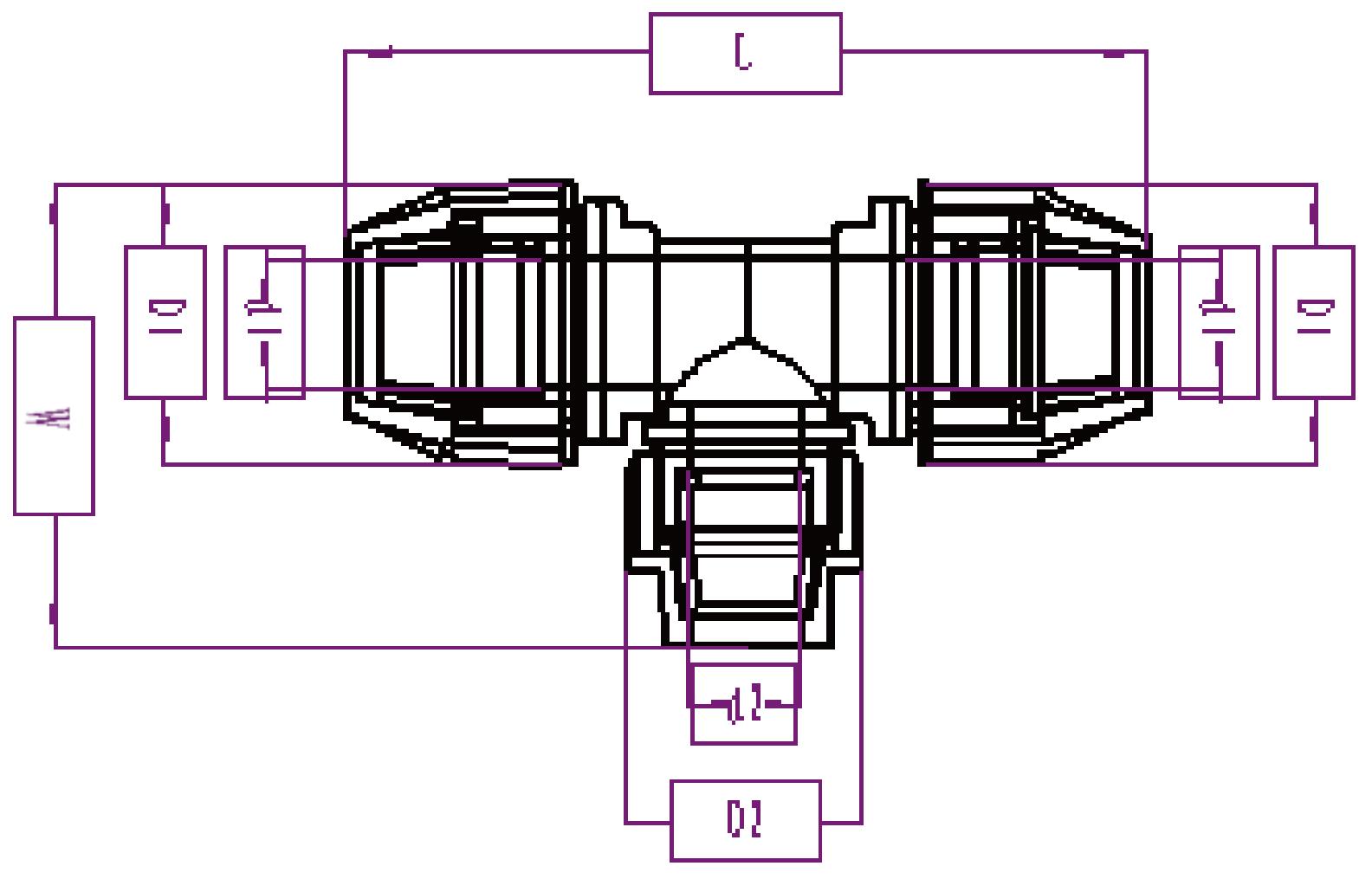

| REDUCING TEE | ||||||

| SIZE | D1 | D2 | d1 | d2 | L | W |

| Φ25X20X25 | 56 | 44 | 26 | 21 | 158 | 93 |

| Φ32X25X32 | 65 | 56 | 33 | 26 | 189 | 105 |

| Φ40X32X40 | 80 | 65 | 41 | 33 | 239 | 123 |

| Φ50X40X50 | 92 | 80 | 51 | 41 | 265 | 165 |

| Φ63X50X63 | 114 | 92 | 64 | 51 | 303 | 185 |

| Φ75*63*75 | 128 | 114 | 76 | 64 | 365 | 225 |

| Φ90*75*90 | 152 | 128 | 91 | 76 | 420 | 270 |

| Φ110*90*110 | 182 | 152 | 111 | 91 | 486 | 310 |

STRUCTURE DIAGRAM:

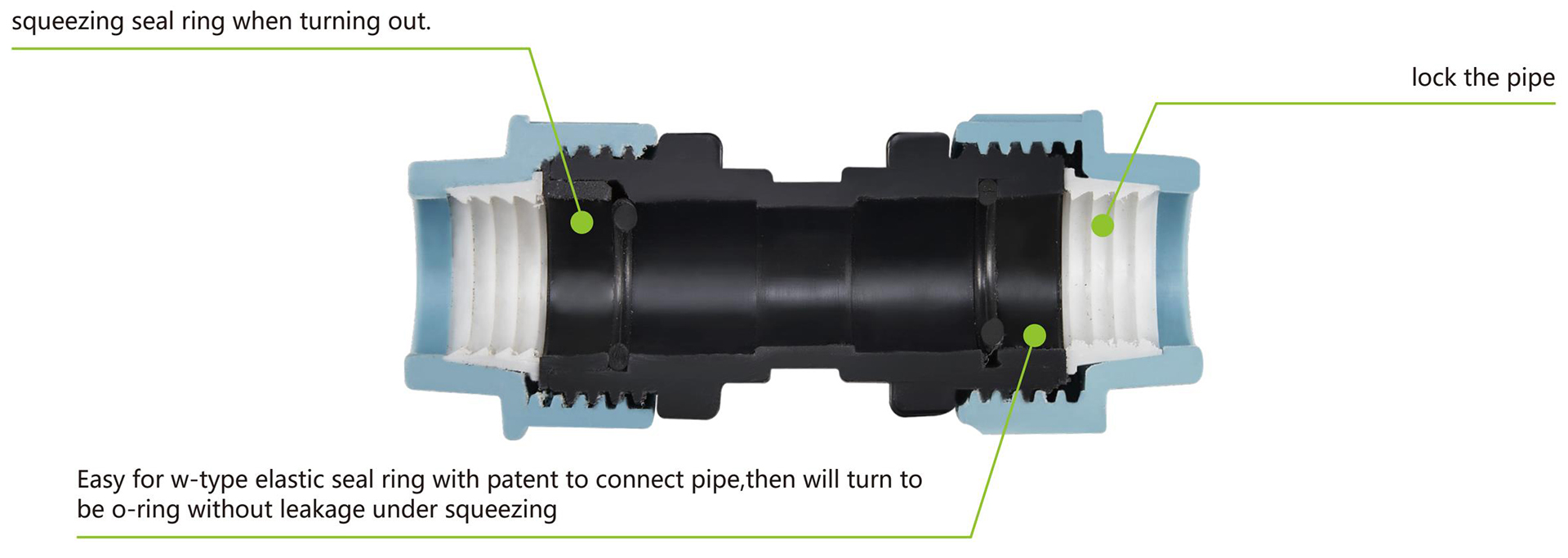

1、Polypropylene with dye master of high stability to UV rays and solidity to heat

2、Heterophasic block polypropylene(PP-B) for exceptional mechanical properties even athigh temperature

3、Lock the pipe

Working Pressures:

Allows the maximum working pressure(PN-PFA")OF 16 bar(UNl 9561-2)for diameters from 16 to 63 and PN 10 for diameters from 75 to 110, at the temperature of 20℃ . Maximum allowable working pressures related to the duration of pressure and temperature.

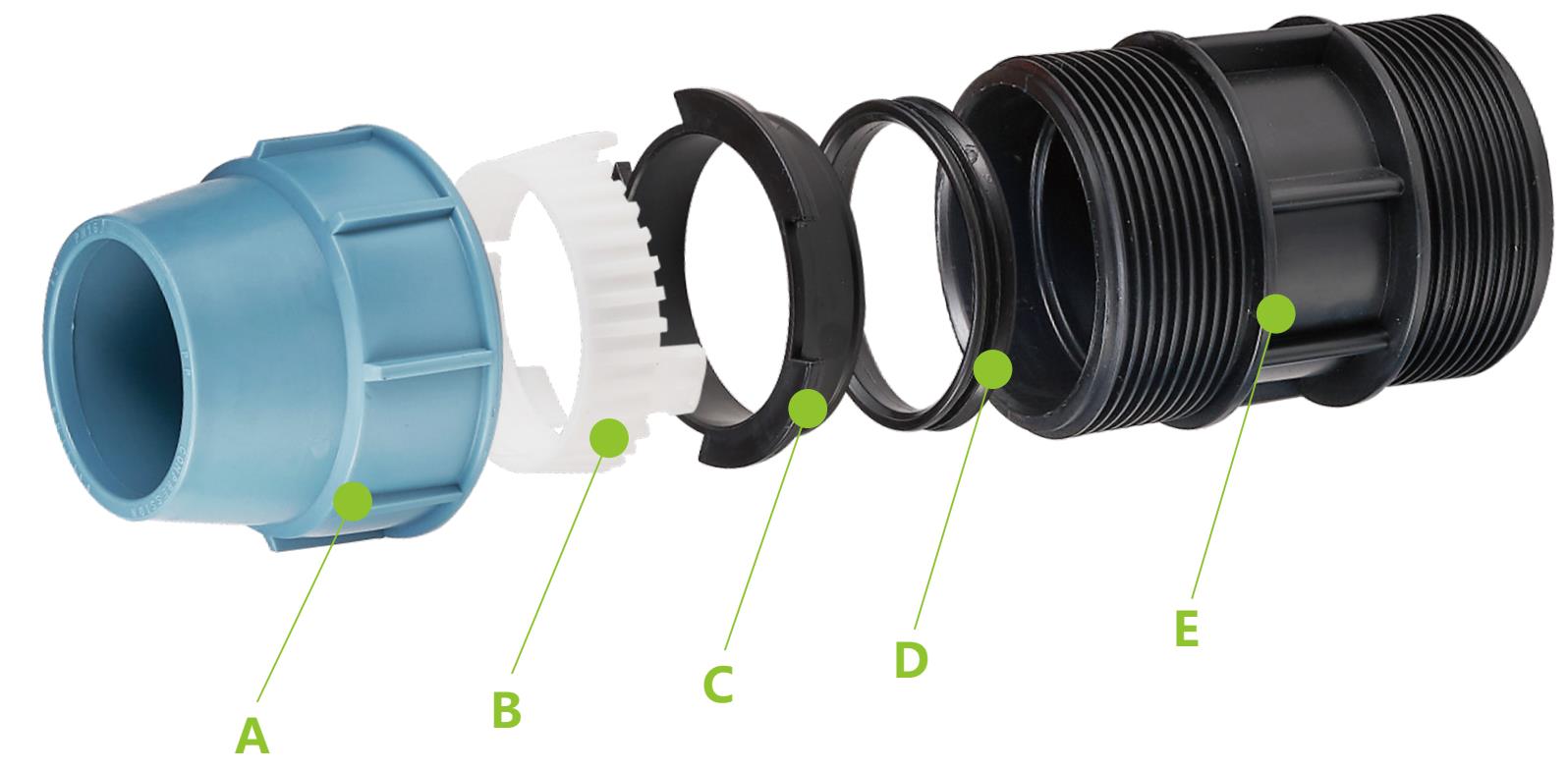

| S/N | part | material | pressure |

| A | nut | PP | PN16(20MM-63MM) PN10(75MM-110MM) |

| B | chinching ring | POM | |

| C | blocking nut | PP | |

| D | O-ring | NBR | |

| E | body | PP |

A-Nut

Polypropylene with dye master of high stability to UV rays and solidity to heat.

B-Clinching ring

Polyacetal resin(POM) of high mechanical resistance and hardness.

C-Blocking bush

Polypropylene.

D-O Ring gasket

Special elastomeric acrylonitrile rubber(NBR) for alimentary use.

E-Body

Heterophasic block polypropylene(PP-B) for exceptional mechanical properties even at high temperature.

Our market share of our products has greatly increased yearly. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future. We are looking forward to your inquiry and order.

Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!