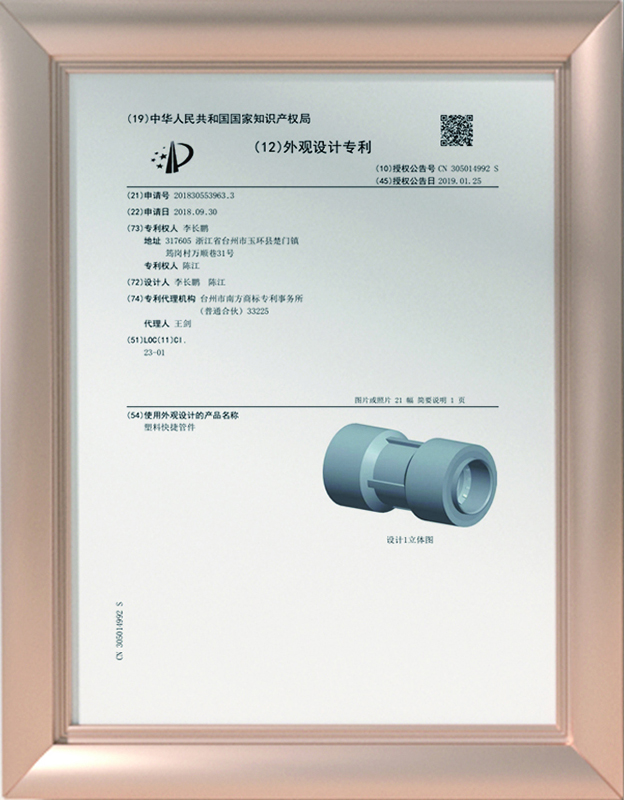

COUPLING

We has more than ten years of experience in the production and export of plastic valve/pipe fittings. with the development of the company, we have added our production machines, production technology and production procedures, greatly improving our production efficiency and greatly quick delivery time .If you are interested in our factory, welcome to visit our factory in China. The entire production process, from product conception to delivery to the customer, guarantee the highest quality and to minimize errors.

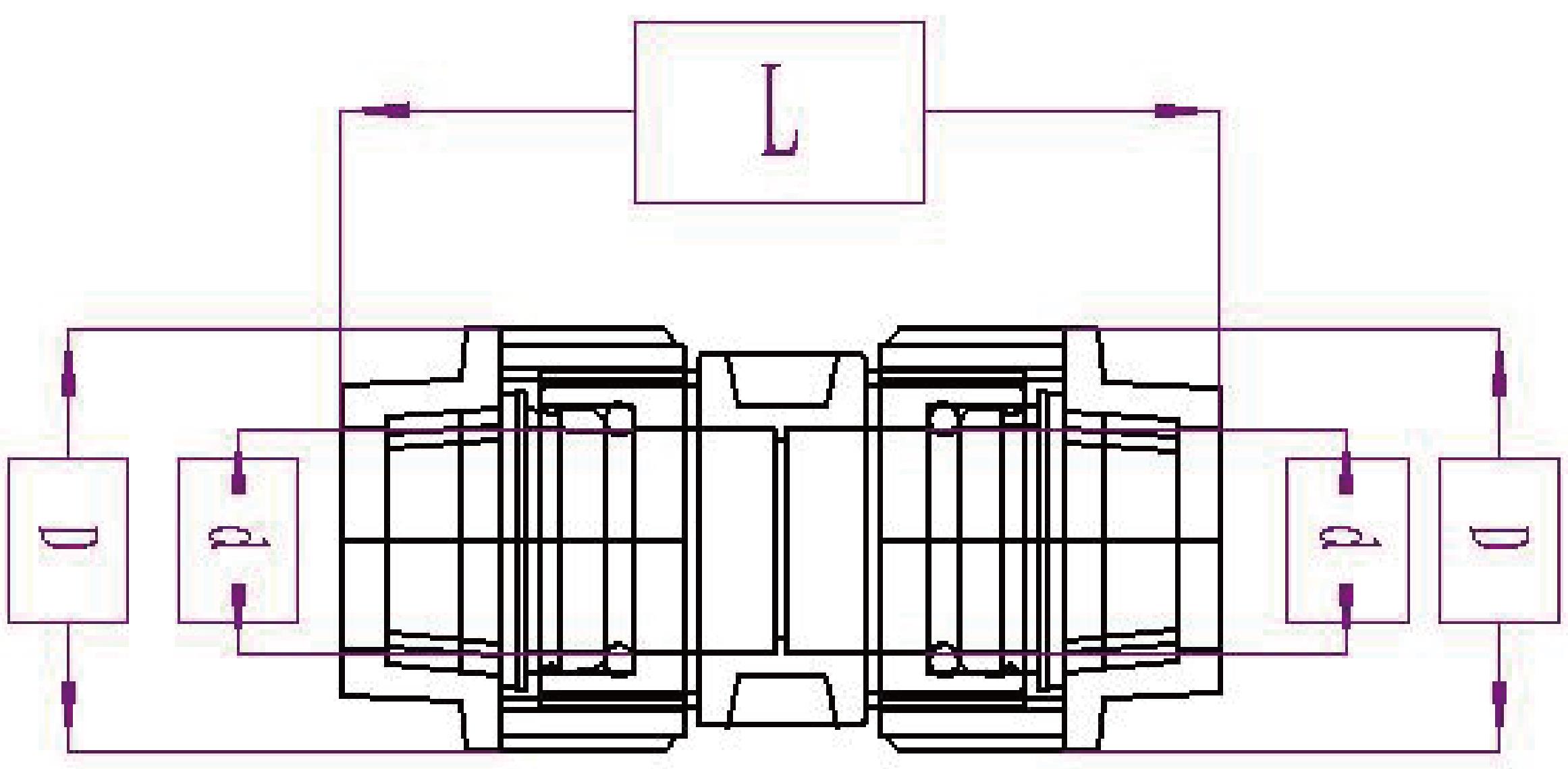

| COUPLING | |||

| SIZE | D | d | L |

| Φ20 | 44 | 21 | 100 |

| Φ25 | 56 | 26 | 130 |

| Φ32 | 65 | 33 | 150 |

| Φ40 | 80 | 41 | 195 |

| Φ50 | 92 | 51 | 218 |

| Φ63 | 114 | 64 | 235 |

| Φ75 | 128 | 76 | 280 |

| Φ90 | 152 | 91 | 315 |

| Φ110 | 182 | 111 | 360 |

STRUCTURE DIAGRAM:

1、Polypropylene with dye master of high stability to UV rays and solidity to heat

2、Heterophasic block polypropylene(PP-B) for exceptional mechanical properties even athigh temperature

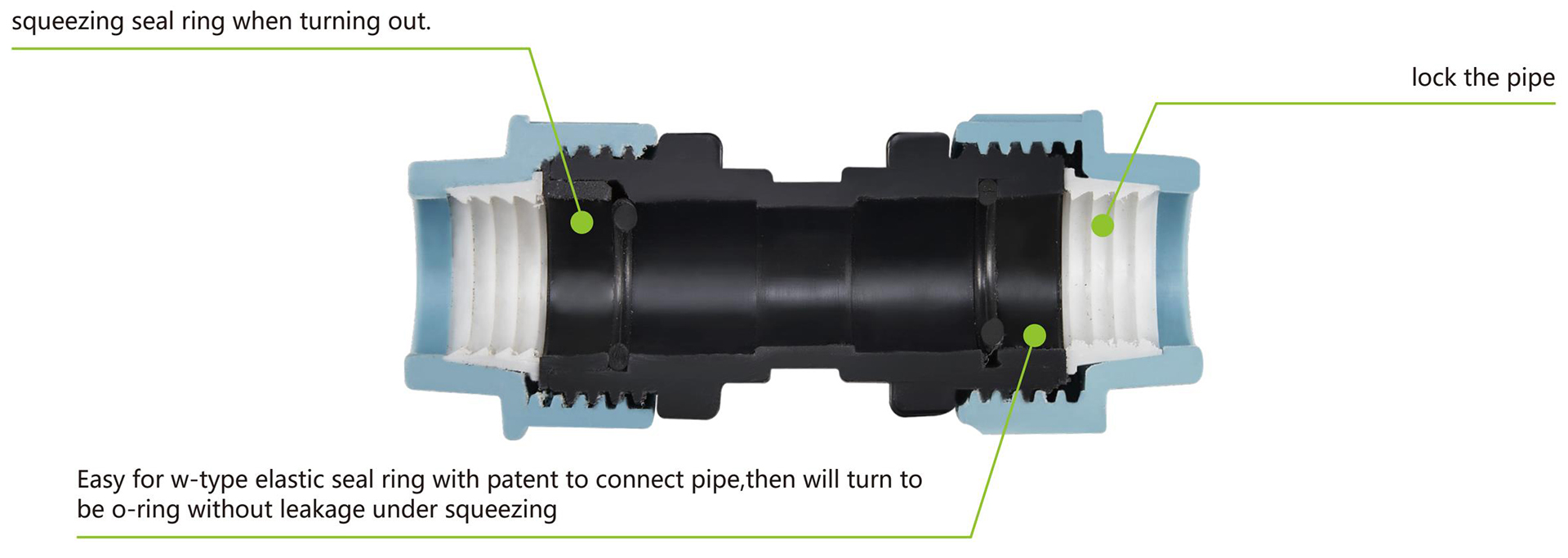

3、Lock the pipe

Working Pressures:

Allows the maximum working pressure(PN-PFA")OF 16 bar(UNl 9561-2)for diameters from 16 to 63 and PN 10 for diameters from 75 to 110, at the temperature of 20℃ . Maximum allowable working pressures related to the duration of pressure and temperature.Factory direct sales are fast and direct, with long wear-resistant life, no need for hot-melt, precision forging, through the team's exquisite craftsmanship, high pressure resistance, strong and durable.

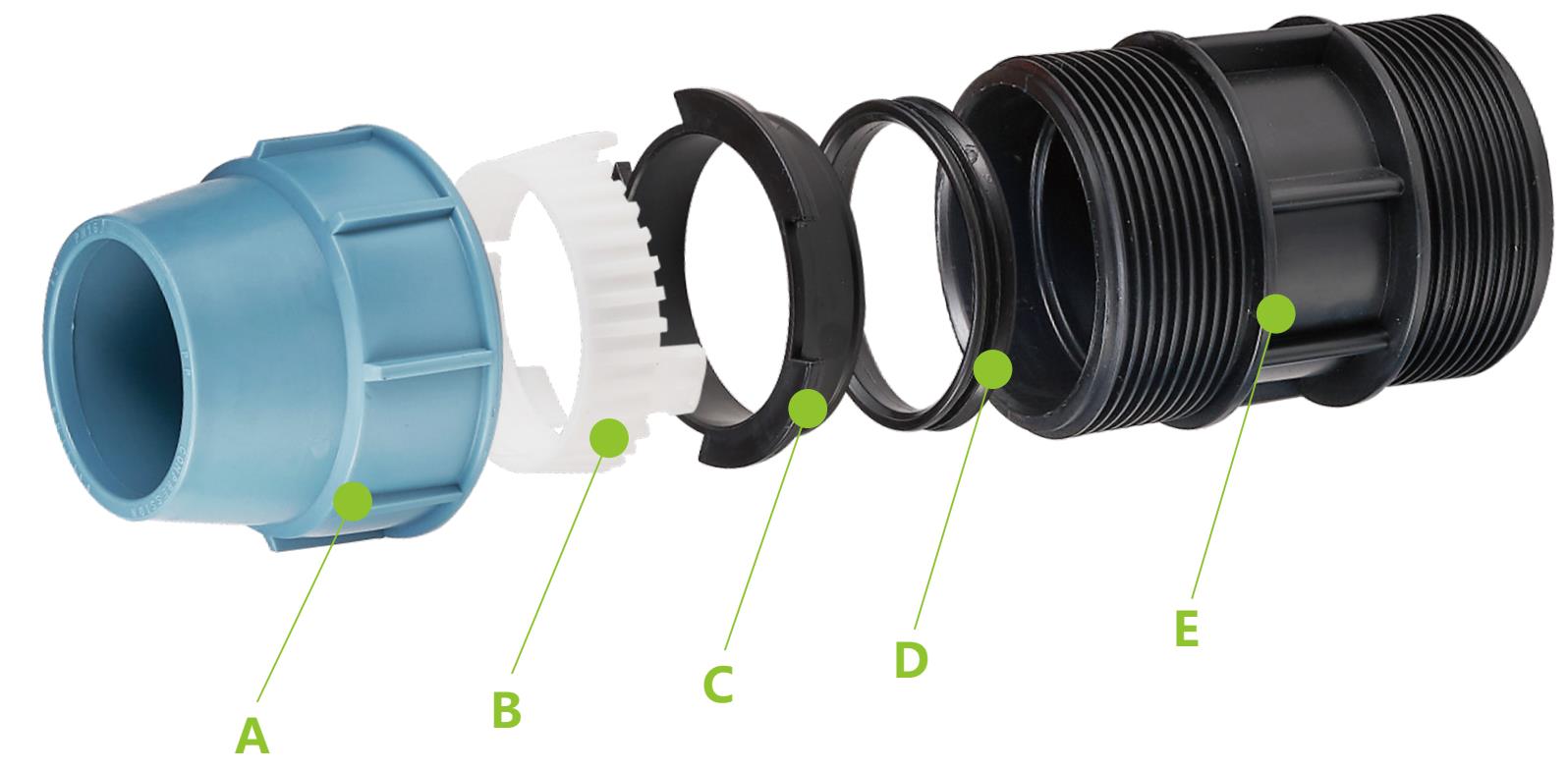

| S/N | part | material | pressure |

| A | nut | PP | PN16(20MM-63MM) PN10(75MM-110MM) |

| B | chinching ring | POM | |

| C | blocking nut | PP | |

| D | O-ring | NBR | |

| E | body | PP |

A-Nut

Polypropylene with dye master of high stability to UV rays and solidity to heat.

B-Clinching ring

Polyacetal resin(POM) of high mechanical resistance and hardness.

C-Blocking bush

Polypropylene.

D-O Ring gasket

Special elastomeric acrylonitrile rubber(NBR) for alimentary use.

E-Body

Heterophasic block polypropylene(PP-B) for exceptional mechanical properties even at high temperature.